| The wax maquettes that were encased in investment molds last week (see blog entry for 3/15/14) were loaded into the kiln and subjected to a burnout temperature of approximately 1,250 degrees for 30+ hours. This process removes all of the wax from the molds and dries out the investment. After the kiln cooled to a manageable temperature, the still warm molds were removed and lined up on a shallow bed of dampened sand. Long wooden flasks (frames) were placed around the molds and dampened sand was tamped in around them to within a couple of inches of the top of the molds. The sand serves to contain any spilled bronze and to insulate the molds. While we readied the molds, bronze ingots were melted in a crucible in the furnace at a temperature of about 2000 degrees. The crucible can hold over 200 pounds of melted bronze. When we finished packing the wooden flasks with sand and the bronze was hot, the pour team suited up in their protective garments (face shields, leather jackets, and flame resistant chaps). The furnace was shut down and the hot crucible of bronze was removed using crucible tongs and an overhead hoist system. The crucible was then locked into a pouring shank attached to the hoist, moved along the overhead support beam, and lowered into position over the first of the molds. The hot bronze was poured into the mold until it was full and then the pour team moved down the line of molds and repeating the process. After the first 8 molds were poured the bronze had to be returned to the furnace for reheating to insure that the remaining molds would be effectively filled. (If the bronze is too cool it can solidify before the mold is completely filled.) A second pour teamed filled the remaining molds with the second crucible of bronze. Once the bronze in the molds cools, the real work will begin. The gated bronze will have be broken out of the investment molds and any remaining investment will have to be cleaned off the surface of the bronze. Next the gating and fill cup will be cut away from the sculpture casts. The removal points will have to be chased and resurfaced, as will any areas with surface imperfections. This part of the process takes time and a lot of "elbow grease" Stay tuned! |

|

0 Comments

The trickiest sculpture to gate, because I wanted to cast it in one piece instead of doing each part separately and then attaching them later, was going to be the man on the round base with his hand on the door. I decided that the best way to get the most bronze quickly into the piece would be to bottom feed it into the base and vent it out the top of the man's head and the top of the door. I was able to use a vise to hold the main gate while I attached the base at an angle that would allow space for the door and man to be added above the sprue cup. After attaching the sprue cup to the end of the main gate, I set it up in the vise so that the surface of the base was flat. I was then able to attach the door, the man, and his case to the base, and then turn the whole thing upside down and attach the cup to the wooden baseboard. Finally I connected the piece to the baseboard by adding vents from the top of the man's head, his lower shoulder and the ends of the door and the lowest point of the round base. Next! The second maquette that I added was the cow. The challenges for this piece were the delicacy and thinness of some of its parts (the tail, the teats, the ears and legs) and its variety of angles. I decided to vent out through the tail and back legs and to feed the bronze in through the head, ears, and front legs. By the time I finishd gating the teats, it looked as though I had attached the udder to a milking machine. I also made a 'just in case' spare tail and attached it to the gating. The next step was to add the 2 separate seated figures to the gating system. I positioned them so that I could have the bronze enter though sprues placed on top of their heads and shoulders and flow smoothly through the bodies. I vented them out the lowest point of the feet. Additionally, I vented out of the fingers on the right arms, as well as from the chins. The final step was to add additional diagonal braces to the venting to insure that the pieces were securely supported and would not be dislodged either in the journey over potholed and frost heaved roads into Portland or when the investment was poured into the mold. As the first sentence of the blog indicated, the gated maquettes survived both the trip to Portland and the investing process. The actual bronze pour will take place next Saturday and the pieces will be broken out of their molds the following week. Fingers crossed ... stay tuned!

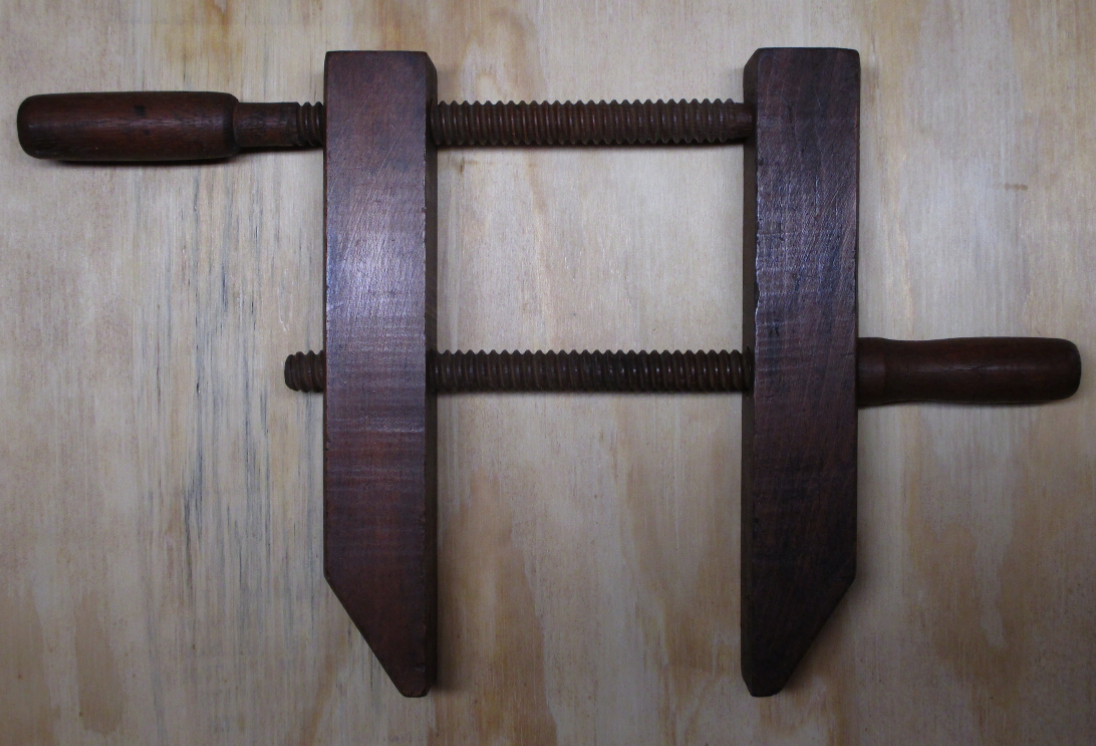

For the past month I have been very busy getting some work ready to be cast in bronze later this month. I will at long last be casting the "stair ball" that I have written about in several of my blog entries (9/11/12, 11/28/12, 10/27/13). In addition, I have made several smaller figural (human and animal) pieces to be cast. The creation of each of the figural pieces involved a common thread in that each piece is paired with a wooden object unearthed from my treasure trove of "it could be used for something someday" items. While cleaning out a closet I came across an old shallow walnut appetizer serving tray, and it occurred to me that it might be just what I needed as a mounting surface for a relief sandcast bronze moon that I had done some time ago. It turned out to be a perfect fit, but it also inspired a new direction for the piece. I immediately decided to create a bronze cow to jump over the moon, a` la "Hey Diddle Diddle". To complete the piece, I will place a small wooden nob top just below the moon and will paint it to look like the earth. The cow jumping over the moon project inspired me to find other objects that might be coupled with small bronze sculptures. This thought led me to an old wooden clamp that had been languishing away in the cellar. I immediately saw it as an effective jungle gym for small human figures... sitting on it, climbing on it, hanging from it, etc. I found myself with multiple ways of setting it up, with multiple arrangements of figures. In the end, I decided to start simple ...two figures seated atop the flat ends of the clamp looking over their shoulders at each other. The clamp itself with eventually be attached by the narrow ends to a base of yellowheart. (I will be looking for more clamps for future variations! ) The final piece that I will be casting resulted from the discovery of a wooden dollhouse door that I had acquired for a project 40+ years ago and never used. Being in a figural frame of mind, I decided that I would make a figure that was either coming or going through the door. The door itself will also be cast in bronze. I have also made a small suitcase or briefcase that will be on the floor to the left of the figure. The fact that the figure is unclothed and he has a suitcase suits my sense of whimsy. The next step will be to get all of these waxes gated and ready to invest... yet another challenge!! Stay tuned!

|

AuthorCynthia Smith, Maine artist, originally from Connecticut. Taught art at secondary level for 35 years, retired in 2004. Sculpts in bronze, wood, stone, clay & plaster. Her work can be seen at several mid-coast Maine galleries and shows. Archives

June 2023

|

RSS Feed

RSS Feed